Explore UV Curing Systems: Guide, Insights, and Key Details for Industrial Use

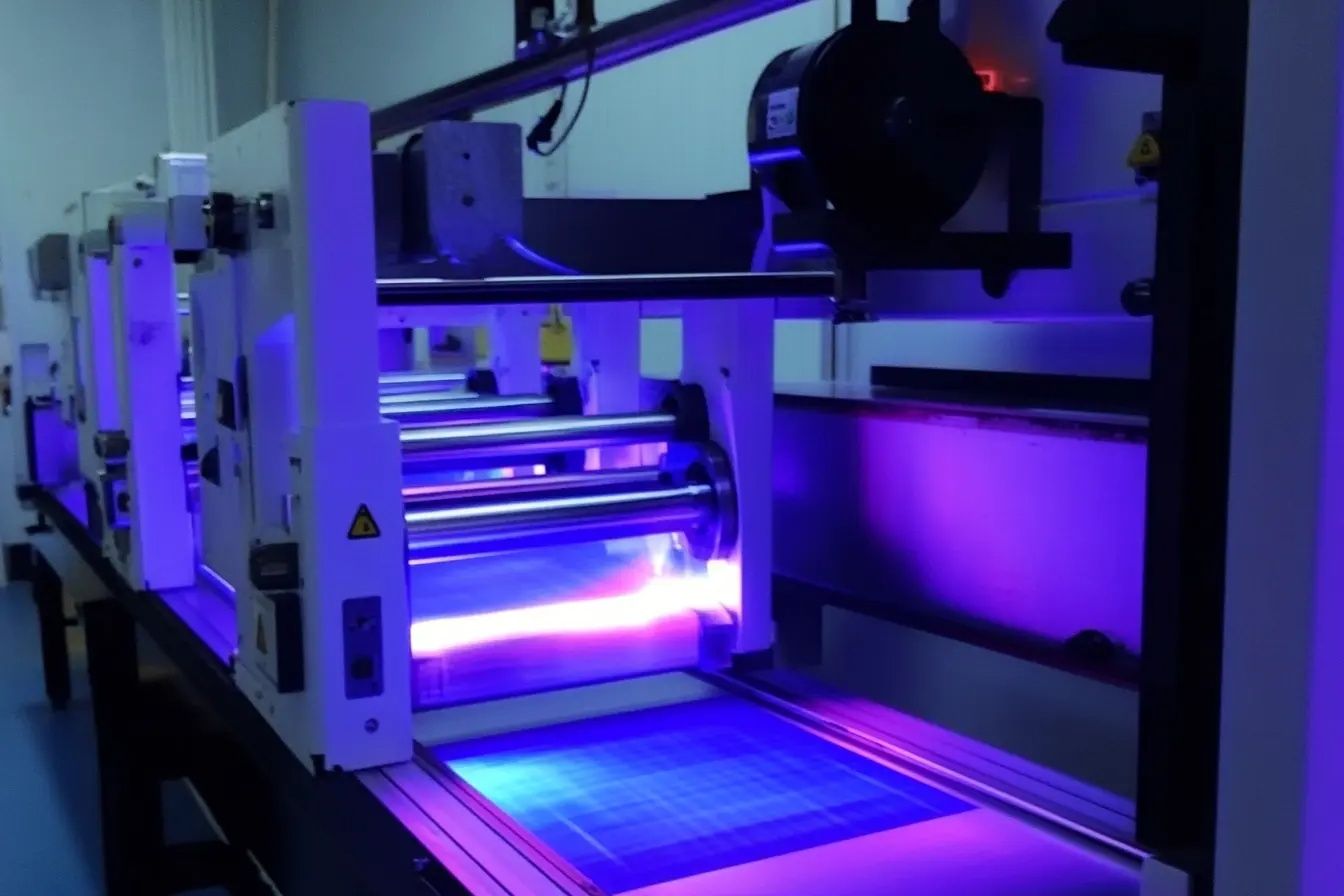

UV curing systems are industrial technologies that use ultraviolet (UV) light to rapidly harden inks, adhesives, and coatings. The process works through a chemical reaction known as photopolymerization, where liquid substances solidify almost instantly under UV exposure.

The technology exists because traditional drying or curing methods, such as heat ovens or air drying, are often slower, energy-intensive, and less precise. Industries like printing, packaging, automotive, electronics, and medical device manufacturing rely on UV curing to improve production speed, reduce waste, and achieve consistent quality.

UV curing first gained traction in the 1960s for printing applications. Over time, advancements in lamp technologies, especially the introduction of LED UV curing, expanded its use across multiple industrial sectors. Today, it is a core part of manufacturing processes that require high precision and efficiency.

Importance

UV curing matters in today’s industrial landscape because it offers several advantages:

-

Speed and efficiency – Curing happens in seconds, reducing downtime and increasing throughput.

-

Quality improvement – Produces durable, high-gloss, and scratch-resistant finishes.

-

Energy savings – LED UV curing systems consume less energy compared to heat-based alternatives.

-

Environmental benefits – Lower emissions and reduced reliance on solvents.

-

Versatility – Works on plastics, glass, metals, paper, and composites.

Who it affects:

-

Manufacturers in printing and packaging – for labels, cartons, and flexible packaging.

-

Automotive and aerospace companies – for coatings, adhesives, and composites.

-

Electronics producers – for circuit boards, sensors, and displays.

-

Healthcare industries – for curing dental resins, catheters, and medical adhesives.

Problems it solves:

-

Eliminates slow drying times that delay production.

-

Reduces rejects from uneven finishes or incomplete curing.

-

Helps companies meet sustainability goals with cleaner processes.

-

Provides consistency across large-scale manufacturing runs.

Recent Updates

In the last year, several trends and updates have shaped the UV curing industry:

-

Expansion of LED UV curing (2024–2025): LED-based systems are replacing mercury lamps due to lower energy consumption and longer lifespans.

-

Smart manufacturing integration (2025): UV curing equipment is increasingly connected with automation platforms for predictive maintenance and real-time monitoring.

-

Growth in 3D printing applications (2024): UV curing is central to additive manufacturing processes using resins.

-

Sustainability-driven innovation (2024): Companies introduced eco-friendly UV-curable materials with reduced volatile organic compounds (VOCs).

-

Regulatory adaptation (2025): Stricter emissions standards in Europe and North America encourage adoption of UV curing systems over traditional solvent-based methods.

Laws or Policies

UV curing technology is subject to several regulations and industrial standards worldwide:

-

Environmental rules: Many countries enforce limits on VOC emissions, encouraging industries to adopt UV-curable coatings and inks.

-

Occupational safety: Operators working with UV lamps must follow guidelines from agencies such as OSHA in the US or EU-OSHA in Europe, focusing on eye and skin protection.

-

Mercury reduction policies: The Minamata Convention on Mercury has influenced a global shift toward LED UV curing to replace mercury vapor lamps.

-

Medical and electronics compliance: For industries like healthcare and electronics, FDA (US), CE (Europe), and ISO standards regulate the safe use of UV-cured materials.

These policies drive industries to adopt safer, greener, and more efficient UV curing systems.

Tools and Resources

Several tools and resources support the adoption and optimization of UV curing systems:

-

Equipment and software platforms

-

LED UV curing lamps and conveyor systems

-

UV intensity meters and radiometers for monitoring performance

-

Simulation software for curing profile analysis

-

-

Websites and associations

-

RadTech International – educational resources on UV curing

-

European Photopolymer Science Association – research updates

-

Industry 4.0 platforms integrating curing data into digital workflows

-

-

Templates and calculators

-

Energy consumption calculators for comparing UV vs. thermal curing

-

ROI assessment templates for system upgrades

-

Safety checklists for workplace UV exposure compliance

-

Comparison Table: Traditional Drying vs. UV Curing

| Factor | Traditional Heat Drying | UV Curing Systems |

|---|---|---|

| Drying Speed | Minutes to hours | Seconds |

| Energy Use | High (heat-based ovens) | Low (LED UV options) |

| Environmental Impact | VOC emissions | Low to zero VOCs |

| Durability of Finish | Variable | High, scratch-resistant |

| Equipment Footprint | Large ovens and dryers | Compact curing stations |

| Scalability | Moderate | High across multiple sectors |

FAQs

What industries use UV curing systems the most?

UV curing is widely used in printing, packaging, automotive, aerospace, electronics, and medical device manufacturing.

What is the difference between mercury UV lamps and LED UV curing systems?

Mercury lamps emit broad-spectrum UV light but consume more energy and contain hazardous mercury. LED UV curing systems are energy-efficient, longer-lasting, and environmentally safer.

Is UV curing safe for workers?

Yes, when proper safety measures such as shielding, protective eyewear, and training are in place. Regulations guide safe workplace exposure to UV radiation.

Can UV curing be used for 3D printing?

Yes, UV curing plays a key role in resin-based 3D printing technologies, solidifying layers of material with precision.

How does UV curing support sustainability goals?

UV curing reduces VOC emissions, lowers energy usage, and eliminates the need for solvent-heavy processes, aligning with global green manufacturing initiatives.

Conclusion

UV curing systems have transformed industrial production by offering speed, precision, and energy efficiency across multiple sectors. From printing to medical device manufacturing, the ability to instantly cure coatings, adhesives, and resins has become essential for modern supply chains.

Recent advances in LED UV curing, smart manufacturing integration, and eco-friendly materials are shaping the next wave of innovation. At the same time, regulations and safety standards ensure responsible adoption.

For businesses and industries navigating the shift toward sustainability and efficiency, UV curing systems provide a reliable and future-ready solution that balances productivity with environmental responsibility.